Bassonomy - our methodologies

//Under construction

Why we test

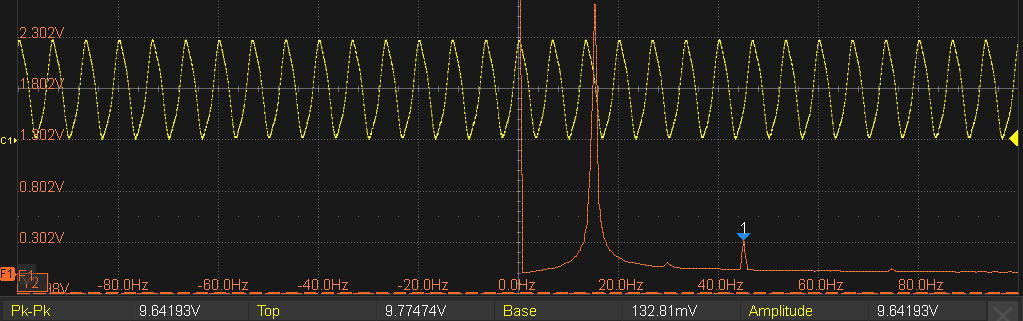

Thiele & Small parameters describe small-signal, linear behavior - useful, but not for how speakers are used in the real world. Bass drivers must be evaluated under large signals, thermal/power stress, and real-world loads to reveal behavior that matters for performance and reliability. We measure those conditions so readers get results that actually predict real use.

Our testing is structured, repeatable, and measurement-driven. We use large-signal tests to show how a driver behaves under realistic load - and sometimes extreme - operating conditions, not just the small-signal T&S parameters.

What we measure

We focus on electro-mechanical and practical performance markers that reveal how a driver behaves under load:

- Large-signal response (how the cone/motor behaves with big inputs).

- Overload & instability tolerance (things that lead to distortion or damage).

- Power/thermal stability across the audible range.

- Mechanical resilience and repeatability after stress.

How scoring works

- Each subtest produces a 0–100% score derived from practical performance margins.

- All drivers are evaluated using the *same baseline performance criteria.

- All technical tests carry equal weight; the overall performance score is the arithmetic mean of all subtest scores.

- Price is not part of the numerical score (market prices fluctuate and don’t map directly to driver physics). Price is a separate eligibility/context factor.

*purpose-built drivers, such as subsonic or SPL-oriented designs may be exempted from the 50 Hz power test without penalty, recognizing that such units are not engineered for sustained linear excursion at that frequency. In these cases, the 40 Hz power test is conducted with a 50% higher allowable input range to proportionally reflect the design’s intended operating bandwidth. Same goes for THD tests, that will be conducted at 40Hz. 30 Hz tests might be applied for extreme niche specialty effect units.

This standardized adjustment maintains a fair comparison across different driver types while keeping the scoring system simple, consistent, and repeatable — even when manufacturer specifications are incomplete. To qualify for this adjustment, a driver must have a specified Xmax greater than 16 mm and be implied or explicitly described as a subsonic or specialty unit.

Limitations and Gaps

While our testing covers a wide range of driver behaviors, it’s not fully exhaustive. Some aspects of driver performance - such as full-spectrum harmonic and intermodulation distortion (THD/IMD) may not be fully captured in our standard test suite. Or a specialty driver might not qualify well in our standarized tests. We recognize all this and treat our measurements as a foundation for interpretation, not an absolute truth. Whenever anomalies are suspected, we supplement additional tests with listening observations and targeted re-measurements to ensure the most balanced possible assessment.

There are both solvable and unsolvable gaps in our methodology, yet the set is assembled in a way to give best practical insights in the shortest form.

Additionally, Klippel/Dumax testing is being considered, but make no mistake: with the usually provided data sets, the issue unfortunately remains the same with these approaches to testing.

The complete test procedures and calculation rules are documented in our full methodology PDF (available for download below).

Bassometry Approved - badge criteria:

Additionally to our standard driver score, a driver may receive the "Bassometry Approved" badge. Such driver must meet these transparent conditions, ensuring excellent behavior and value:

- Scoring: No individual test score may be 0%, and the overall score must be at least 80%.

- Pricing: The driver’s price must not exceed 50% above the typical cost for its performance class.

- Performance markers: The driver must complete our tests without damage or severe instability, demonstrating robust, predictable behavior under stress.

- Exigent circumstances: Rare exceptions may be made if a driver radically outperforms expectations elsewhere (for example, extraordinary performance at an unusually low cost, or a design whose value cannot be captured by standard metrics).

... Or, of course, if the review was paid for handsomely by the lender. Kidding! I´m kidding! Each exception will be well documented or explained in the review for full transparency.